Ford recently unveiled its new 1.5L Ti-VCT engine. This engine has been designed and developed by the engineering team at Ford India and is the first 1.5-litre 3-cylinder natural aspirated petrol engine from the company.

Can’t see the video here? Head to YouTube

Ford’s Sanand Vehicle Assembly and Engine Plant, in Gujarat produces the sub-four meter compact sedan, Ford Aspire, the new Figo hatchback and Ford KA+ (for exports). It is also the global hub for low displacement engines. This plant has an annual capacity to manufacture 2,40,000 vehicles and 2,70,000 engines.

We got a glimpse of how the new Ford 1.5L Ti-VCT petrol dragon engine is being made inside this state-of-the-art facility. At the start of the tour the team behind the development of this new engine gave us a presentation about it and explained the various techniques and innovations utilized. Followed by a detailed safety instruction presentation, we headed off to witness the unveiling of the all-new Ford 1.5L Ti-VCT engine.

You can read more about this engine here: Ford introduces Made-in-India All-New 1.5-litre Ti-VCT Petrol Dragon Engine

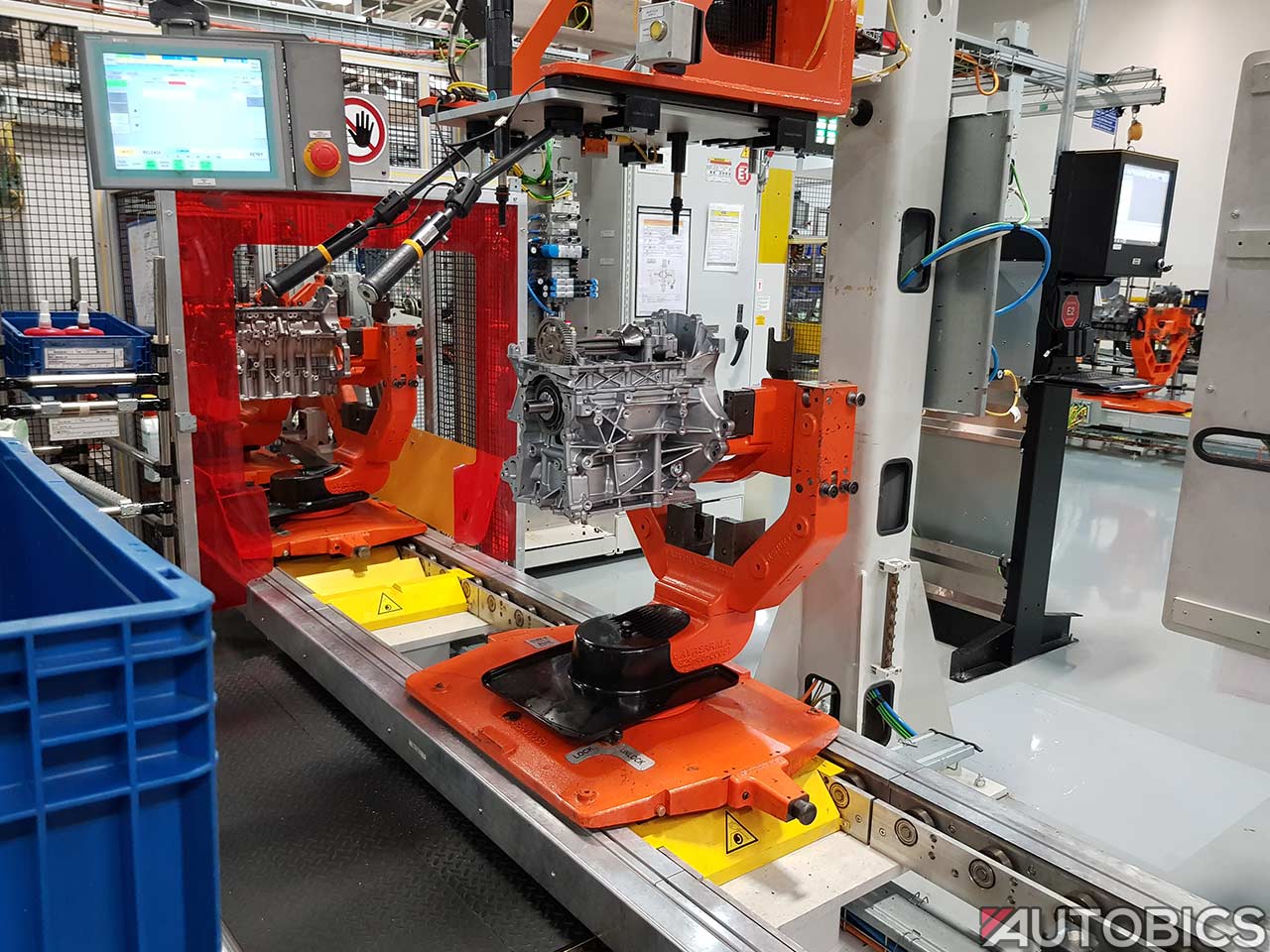

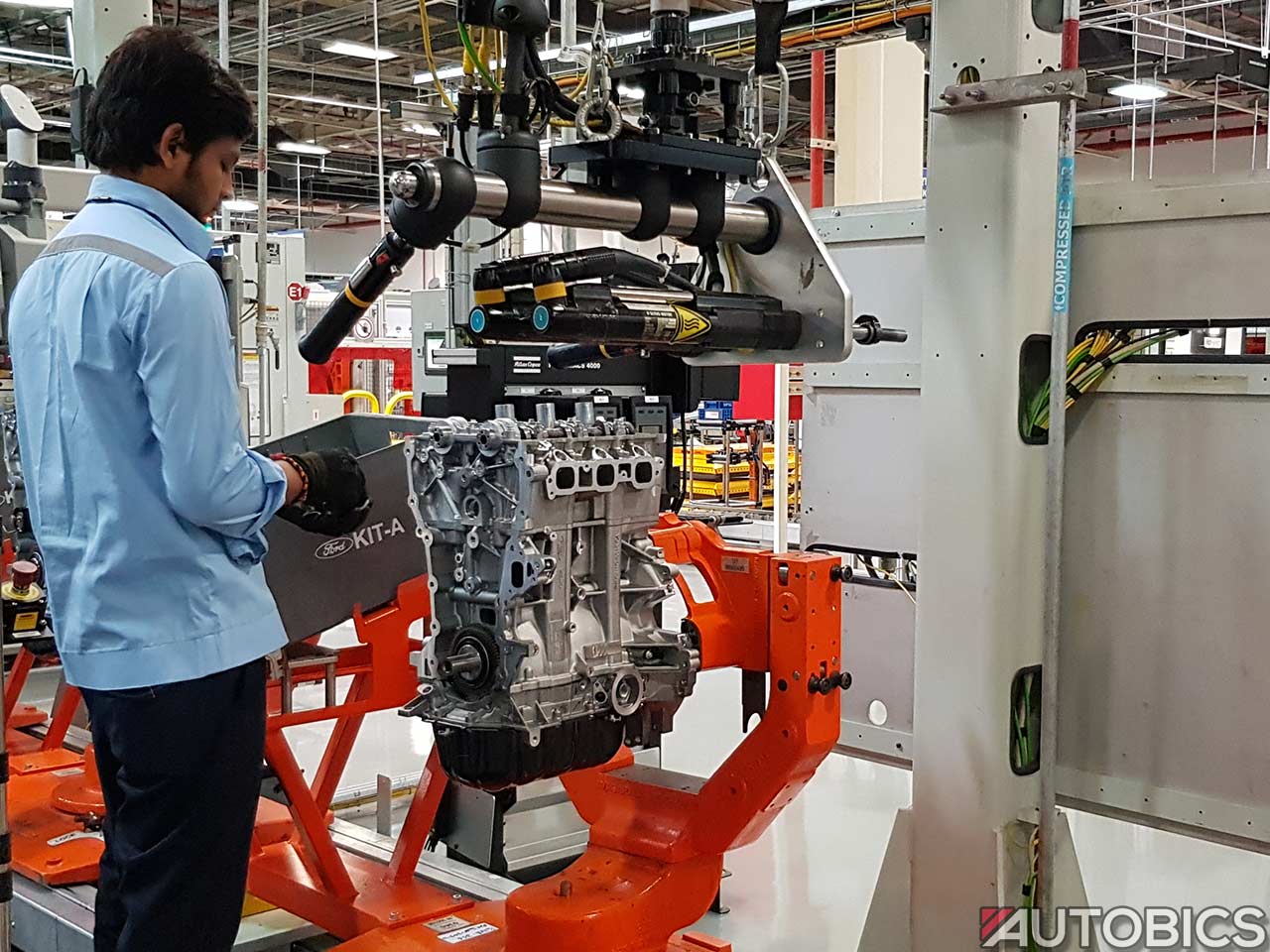

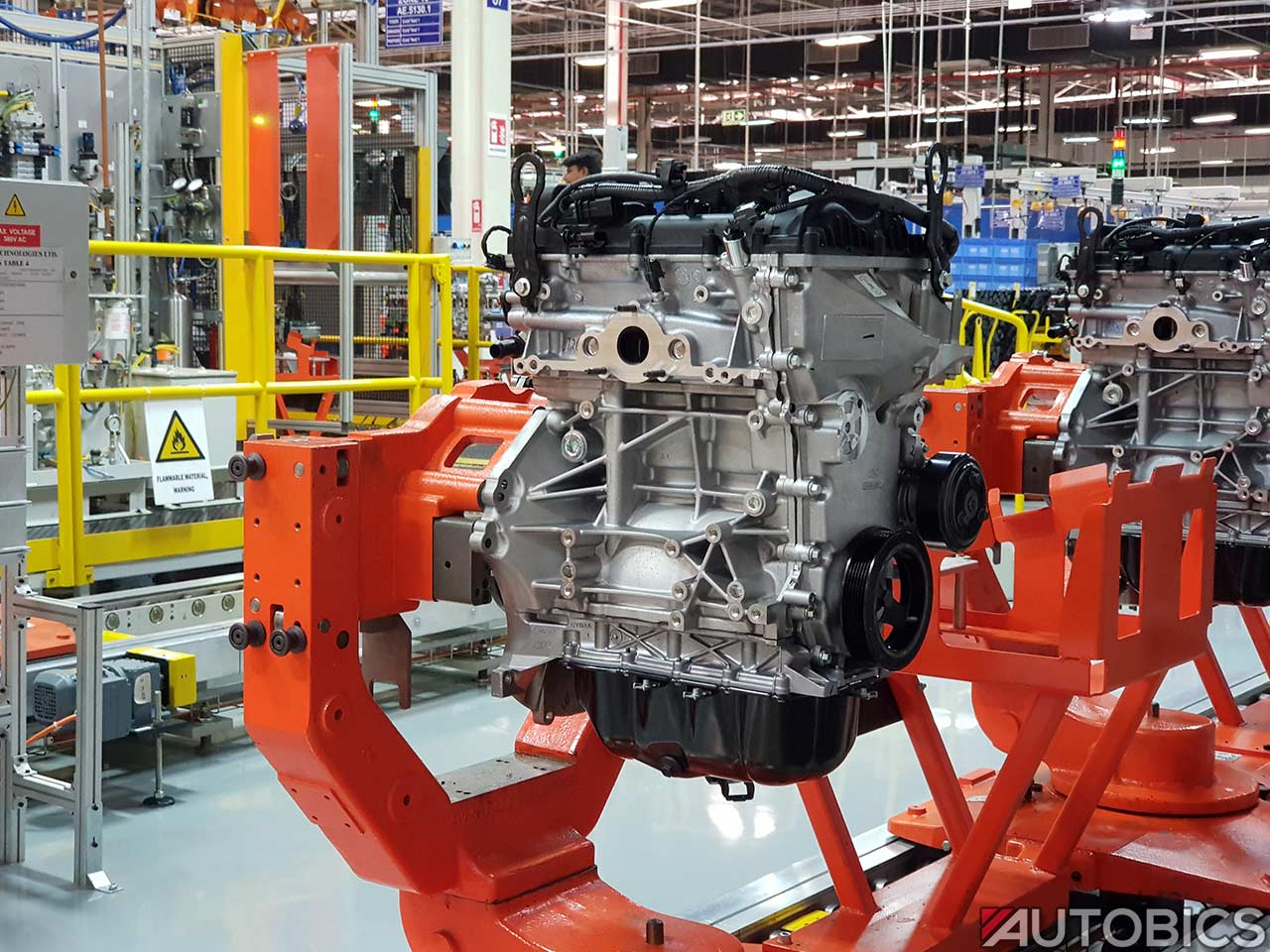

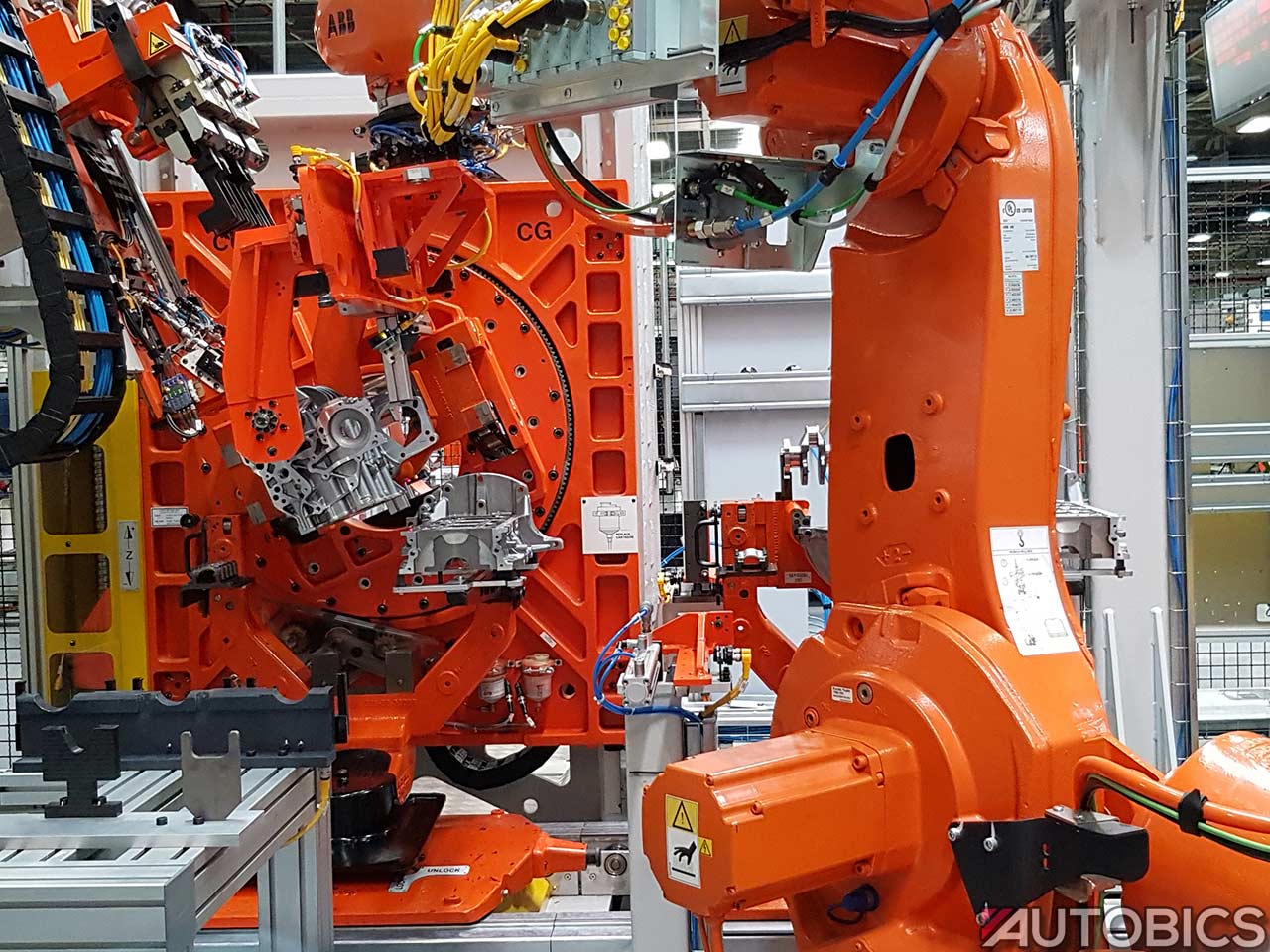

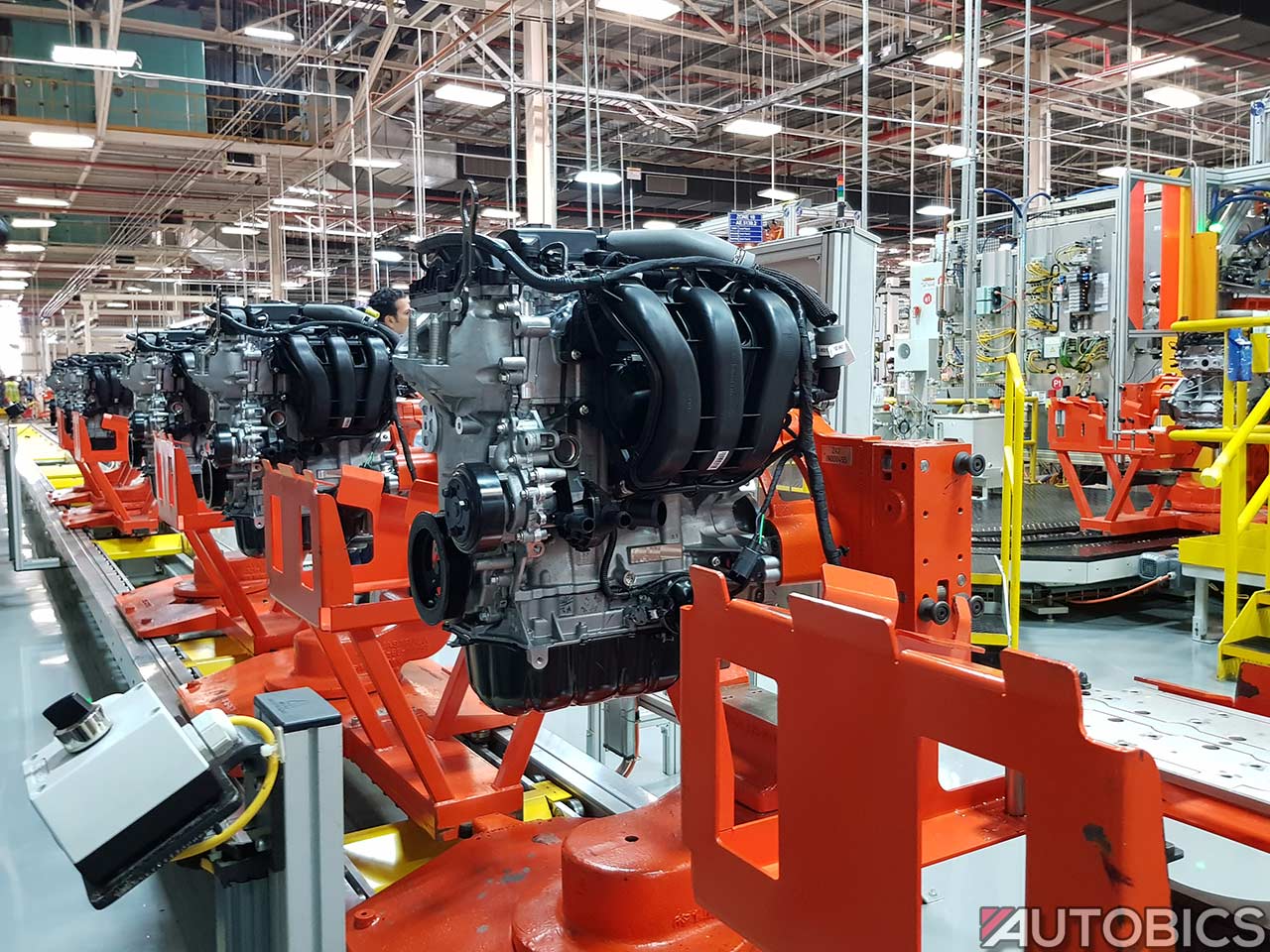

Ford 1.5L Ti-VCT Petrol Dragon Engine Assembly at Sanand Plant – Images:

The next stop was the engine assembly plant. This place is supposed to be extremely clean to maintain the highest quality of the products being manufactured here. In order to make sure no external dust particles get inside, every person entering has to walk through a tunnel blowing high-pressure air. This is to ensure that even micro dust particles are removed off the person entering.

Once, inside you get to see the well-lit and clean looking assembly line where the new Ford 1.5L dragon engine is made. One thing we noticed upon entering was, that there was a lot of screeching sounds. This we got to know is a clever solution for another kind of problem faced by such huge facilities.

Huge structures like this plant often face problems of birds like pigeon entering the facility and making it their home. This leads to dirt and other contaminations entering inside which can hamper the quality of the final products. In order to keep them away, sounds of what seemed to be screams from an eagle are played from loudspeakers in a specific interval of time. This helps to keep the unwanted guests away from the plant.

As we walked across this huge facility, we witnessed several processes involved in the assembly of the engine which is carried out by trained technicians as well as highly advanced robots. In areas where there is no space for error and utmost precision is required the robots take over. The engines go through a lot of checks before moving on to the next stage.

Every step is monitored with help of tags and even a single error can cause the whole production line to stop. The assembly line would not move until the problem is identified and rectified. Using tags also helps Ford to collect data at every stage of the assembly. This can be useful to identify a particular problem to pinpoint accuracy and rectify it.

Once the engine assembly is completed it moves to the cold testing facility. Here the motor is tested for various parameters at a slow rpm without any actual combustion happening. The engine is also tested for any kind of leaks using ultraviolet light.

From here the engine moves to the hot test facility, where it is fired up for the first time. After undergoing various tests, the engine is again checked for any kind of problem and leakages using the UV light. Once the motors are checked and pass every parameter, the manufacturing is completed and they are ready to proceed for packaging and then shipping.

This new 1.5L Ti-VCT petrol engine will make its debut in India with the launch of the new Ford Ecosport. The Sanand engine plant will be leading in manufacturing this petrol motor and will also be supplying it for the international markets.