The automotive industry is undergoing a seismic shift toward electrification and sustainability, and with it comes the challenge of reimagining what makes a car exceptional. Among the key differentiators in this new era is sound—or the lack thereof. Recognizing the importance of minimizing noise pollution while maintaining a premium driving experience, BMW Group has officially inaugurated its new Aeroacoustic and Electric Drive Testing Center. This facility represents a pivotal investment in the future of silent, efficient, and luxurious vehicles.

>>> Great Discounts on Car & Bike Accessories <<<

A Cutting-Edge Facility for the Future of Mobility

Located in Munich, Germany, BMW’s state-of-the-art facility is a marvel of engineering. The center combines advanced aeroacoustic chambers and electric drive testing labs to ensure every vehicle meets stringent noise and efficiency standards. With the rise of electric vehicles (EVs), traditional engine sounds have been replaced by the hum of electric motors and other ancillary noises. This facility addresses these challenges head-on, ensuring that BMW’s electric and hybrid vehicles deliver not only sustainability but also unmatched comfort.

Aeroacoustics: Engineering Silence

The aeroacoustic testing chambers are a cornerstone of the facility. These specialized rooms simulate real-world driving conditions, allowing engineers to assess and optimize noise levels. Using advanced microphone arrays and computational modeling, the chambers can pinpoint the sources of wind noise, tire hum, and other disturbances that might infiltrate the cabin.

BMW engineers leverage this data to refine vehicle designs, employing:

- Advanced Soundproofing Materials: Lightweight yet effective materials that dampen external noise without compromising vehicle performance.

- Aerodynamic Enhancements: Designs that minimize wind turbulence, reducing drag and noise simultaneously.

- Precision Testing Techniques: High-fidelity simulations of speeds exceeding 200 km/h to replicate highway conditions.

The result? A cabin experience that’s as serene at high speeds as it is during a quiet drive through the city.

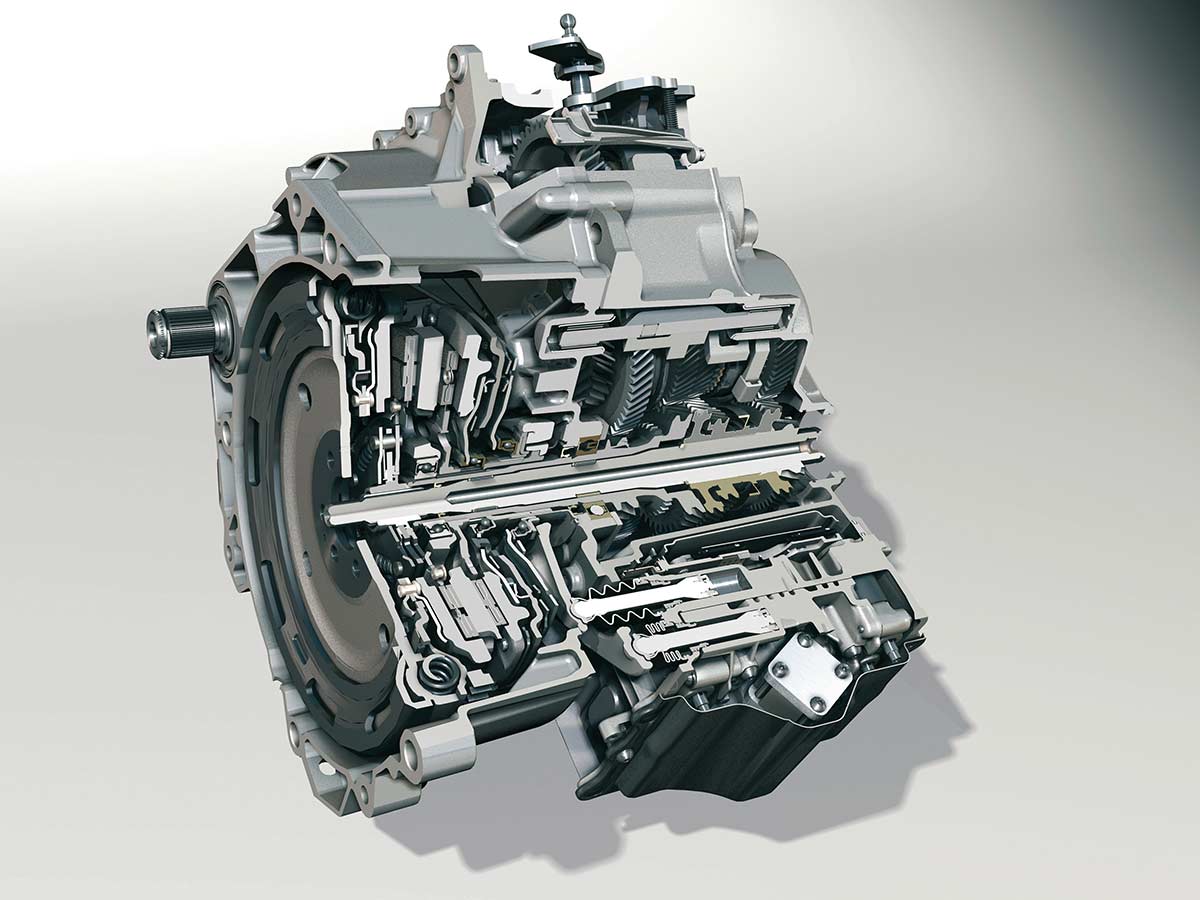

Electric Drive Optimization: Silent and Efficient Power

Beyond aeroacoustics, the facility also focuses on the intricacies of electric drive systems. Electric motors, though quieter than internal combustion engines, produce distinct sounds that must be managed to meet both regulatory and consumer expectations.

Key innovations at the center include:

- Electric Motor Calibration: Fine-tuning the frequency and amplitude of electric motor sounds to ensure they’re non-intrusive.

- Vibration Analysis: Identifying and mitigating vibrations from powertrains and other components.

- Energy Efficiency Testing: Evaluating and improving the interplay between motor efficiency, battery consumption, and overall vehicle performance.

This meticulous approach ensures that BMW’s EVs deliver seamless acceleration and whisper-quiet operation, enhancing the driving experience while maximizing energy efficiency.

Sustainability at the Core

BMW’s commitment to sustainability is evident in every aspect of the new testing center. From energy-efficient building designs to the integration of renewable energy sources, the facility aligns with BMW’s broader goal of achieving climate neutrality by 2050.

The center also facilitates the development of EVs that not only comply with global noise regulations but exceed them, contributing to quieter urban environments and improved quality of life for city dwellers.

A Leap Forward for BMW and the Industry

The inauguration of the Aeroacoustic and Electric Drive Testing Center marks a significant milestone for BMW and the automotive industry as a whole. It underscores the brand’s dedication to innovation, luxury, and sustainability. By investing in advanced technologies and infrastructure, BMW is not only addressing today’s challenges but also paving the way for future generations of vehicles that redefine what it means to drive.

Why It Matters

As electric vehicles become the norm, consumers are increasingly attuned to nuances that differentiate one brand from another. Soundscapes, comfort, and efficiency are emerging as key factors in purchasing decisions. BMW’s proactive approach ensures that its vehicles remain leaders in these areas, offering customers a driving experience that is as sophisticated as it is sustainable.

Quiet Testing for Quiet Cars

BMW’s Aeroacoustic and Electric Drive Testing Center exemplifies the intersection of technology, design, and sustainability. This facility not only enhances BMW’s ability to produce world-class vehicles but also reinforces its commitment to a quieter, greener future. For car enthusiasts and environmental advocates alike, this is a development worth celebrating.

As the automotive world evolves, facilities like this will be crucial in shaping vehicles that deliver more than transportation—they promise an elevated experience, harmonizing innovation with serenity.

Source: BMW